Most of us are familiar with Batik, even if we’ve never actually seen it. It’s often thought of as a decorative fabric that’s associated with South East Asia, and in particular, Indonesia. Think sarongs. But what about the handmade specialised tools that are used to create this fabric, what do we know about them?

The year is 2009. The date Oct 2nd, and UNESCO, the United Nations Educational, Scientific and Cultural Organisation have just announced that Indonesian Batik has made it onto their very selective list as a Masterpiece of Oral and Intangible Heritage of Humanity. While the title is a bit of a mouthful, this is a distinguished proclamation awarded by UNESCO to raise awareness and encourage local communities to protect their unique heritage and support the local people who uphold these forms of cultural expressions. To date, there’s only just over 400 proclamations made by UNESCO world wide, so it’s pretty special.

While the tradition of batik making can be found in many countries, Indonesian batik, particularly that of Java, with its intricate patterns and lavish designs, is some of finest in the world. It’s history dates back hundreds of years and often holds great meaning. Babies were carried in batik slings decorated with symbols to encourage good luck. There were specific patterns for the bride and groom on their wedding day while some designs were reserved exclusively for royalty. One particular regal ceremony saw the casting of royal batik into a volcano! Was it erupting? Who’s to say.

While the tradition of batik making can be found in many countries, Indonesian batik, particularly that of Java, with its intricate patterns and lavish designs, is some of finest in the world. It’s history dates back hundreds of years and often holds great meaning. Babies were carried in batik slings decorated with symbols to encourage good luck. There were specific patterns for the bride and groom on their wedding day while some designs were reserved exclusively for royalty. One particular regal ceremony saw the casting of royal batik into a volcano! Was it erupting? Who’s to say.

The process of creating batik is simple but skilled. It involves applying a pattern onto light coloured cotton or silk with hot wax. The wax acts as a dye-resist, which means the cloth can then be dipped into a vat of dye and then washed under hot water to remove the wax.

This process can be repeated numerous times on the one cloth, creating ever more complex designs.

The traditional art of batik involved drawing patterns onto cloth with wax using a small hand implement known as a tjanting tool, which is pronounced a little like ‘chanting.’ Made from wood, the tjanting looks like a pen with a small metal reservoir and a spout. The reservoir holds the wax, which flows through the spout to create the wax pattern. Simple! But very time consuming. A single sarong can take up to 3 months to create!

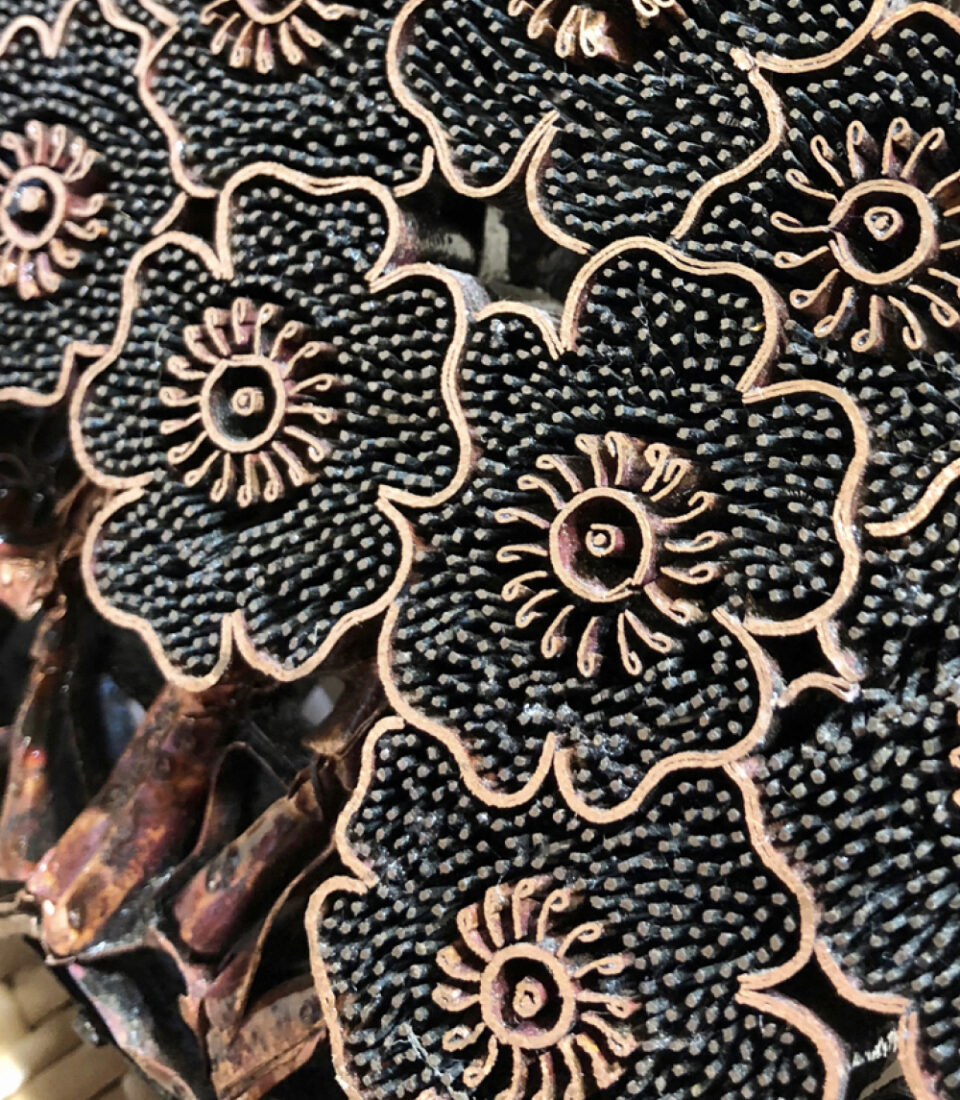

By the middle of the 19th century, with an increase in demand for imported, mass produced European fabrics, the batik industry in Indonesia was on the decline. But the savvy Indonesians were not to be outdone; they wanted to continue creating batik but knew they needed a way to speed up the process. Enter the Tjap, pronounced kind of like ‘chop’, an Indonesian invention that allowed intricate patterns to be printed in wax in less than half the time as the traditional tjanting too. Its invention revolutionised Indonesian batik production.